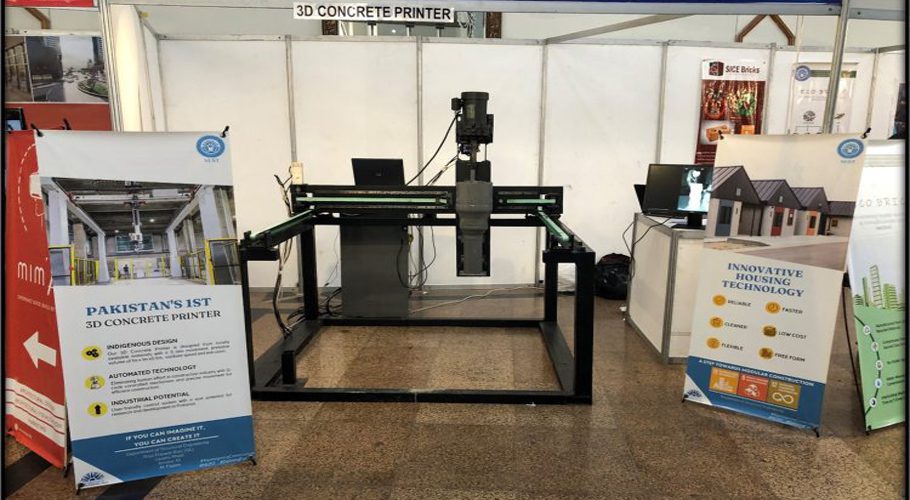

ISLAMABAD: The Structural Engineering Department at NICE – NUST led by Raja Dilawar Riaz under the supervision of Dr. Muhammad Usman have successfully developed Pakistan’s first 3D concrete printer.

NUST says the mix design used by this technology has ingredients the same as conventional concrete but with modified rheological properties to assist in extrudability, buildability, pumpability, and interlayer bonding of printed specimens.

In simpler words, it should have that much workability to be forced out of the nozzle ( low value of dynamic yield stress), but upon settling it should be able to bear its own weight and the weight of subsequent layers added upon it ( high value of static yield stress). Almost all of the materials required in mix design are easily available locally.

It further says with Pakistan being a developing country with an expected expansion of 92% in the construction industry, the construction sector accounts for 2.53% of the total GDP of the country, and with increasing population, there is more pressure on the construction industry to increase its productivity.

It is estimated that there is a current housing shortage of 10 million which is expected to increase up to 13 million by 2025. If fully incorporated into the construction sector, 3D concrete printing offers an inevitable solution to this challenge.

Considering the crisis, students from NUST, Raja Dilawar Riaz, Usama Majid, Ammar Ali, and Muhammad Faizan under the mentorship of their advisor Dr. Muhammad Usman, HoD Structures & Survey Department, NUST Institute of Civil Engineering, have completed the development of Pakistan’s first 3D Concrete Printer.

This indigenous 3D concrete printer has a frame size of 1.2m x 1.2m x 1m. Utilizing its 3-axis movement controlled by servos and gearboxes, a variety of nozzles (with a max size of 3 inches), continuous intake capacity, screw extrusion, and a digital control system, it can print a volume of 1m x 1m x 0.5m.

This inexpensive concrete printer serves as a prototype for large-scale construction applications. It is capable of printing various-shaped architectural and structural components. The concept of using this printer is very simple. A 3D CAD Model is created on computer software and the model is sliced as per the requirement the mach3 controller in this printer reads the G-Code file and extrudes the layer of concrete.

This printer was first time showcased under the theme of “Low-Cost Innovative Housing Technology” at the First International Housing & Property Expo 2022, Islamabad organized by the Federal Ministry of Housing and Works Government of Pakistan.

Nust says development of this concrete printer involved a designed concept developed by few of the literature available and enhancing the output in terms of cost-effectiveness and local availability of resources. The whole development process is an interdisciplinary venture undertaken by this team and completed in the summer of 2022.

This challenging task required multidisciplinary knowledge and expertise which this team learned during the development of this printer. During their course of R&D, they have gone through multiple types of research with respect to civil, mechanical, and electrical engineering and come up with the most efficient solutions. Along with its capability to revolutionize the construction industry of Pakistan, it has widespread potential for sustainable construction and modern research.

Advantages:

This unique prototype of the 3D concrete printer is designed to provide multiple advantages in the construction sector such as:

- Design Flexibility

- Topological Optimization

- Increased Productivity

- Reduced labor effort

- Greater research potential

- Highly precise deposition

- High-end technology-based jobs

- Multifunctionality of structural/architectural elements

- Cost-effective mass housing solution

- Energy efficient

- Promising methodology & output

- Safer construction work

- The balance between beauty, form & function

Owing to the advantages offered by this technology and the success of the development of a 3D Concrete Printer with locally available materials, it is undoubted that this technology will soon revolutionize the construction practices in Pakistan.